The development of a stable and reliable glossy copper plating solution presented us with several challenges, particularly in the selection and dosage of the brightener. In the early phase of our research, we used a brightener that was exceptional in its effectiveness and also had the advantage of remaining stable over very long coating times. Even with coating processes lasting hours, the gloss could be maintained for many hours, while other gloss formers in comparable applications degraded much faster.

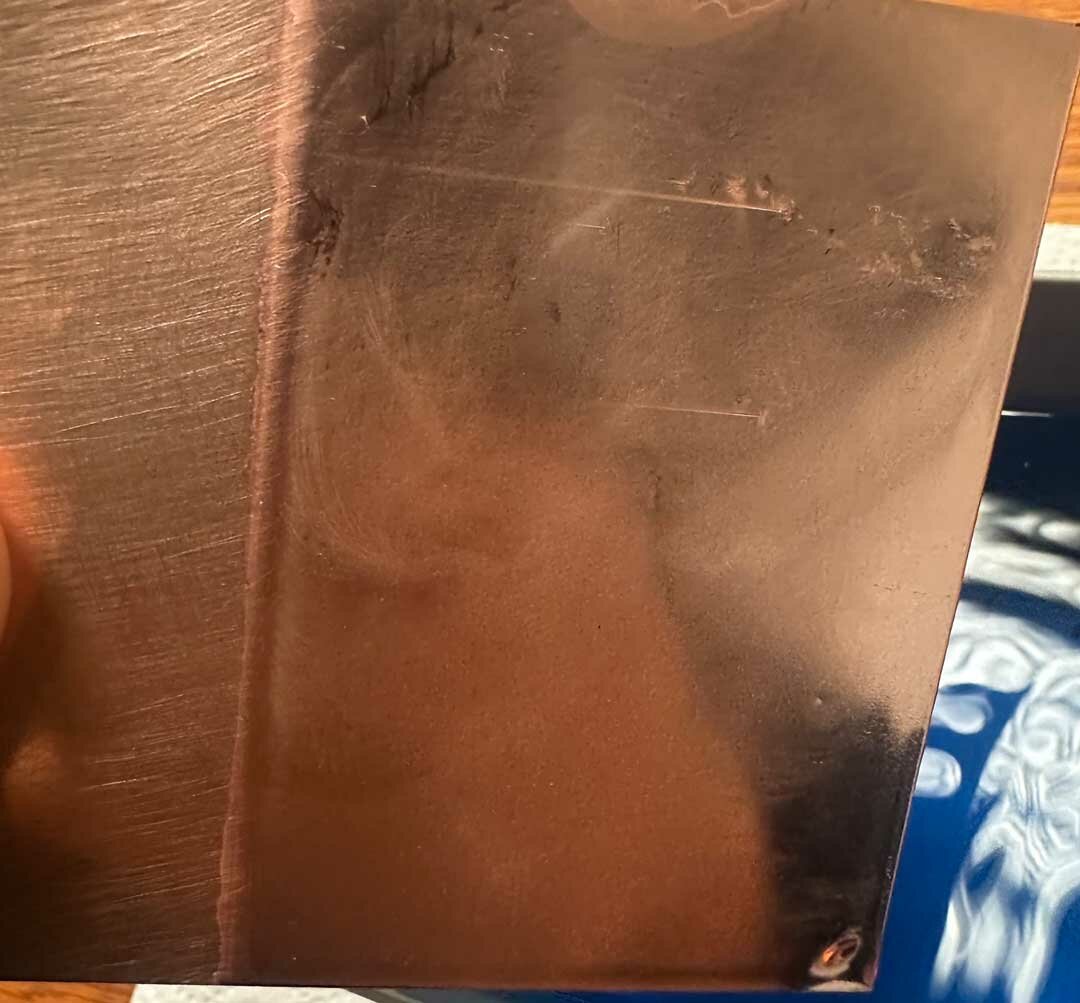

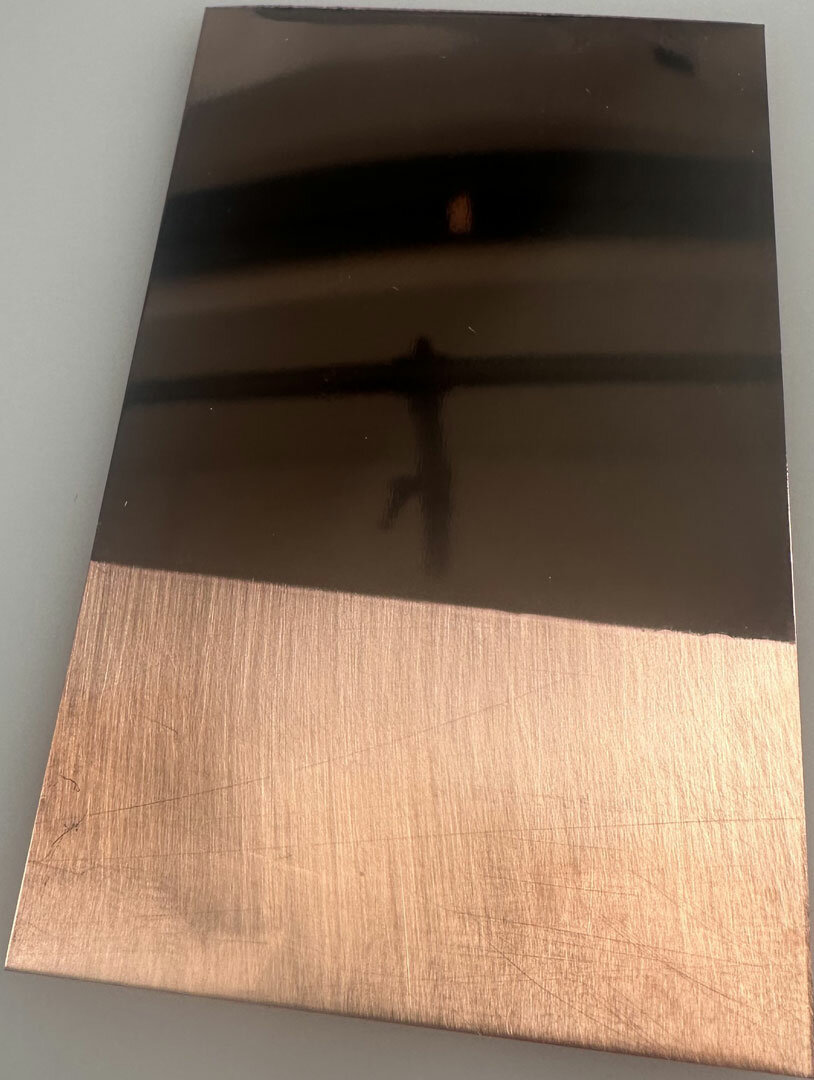

However, this brightener also reacted extremely sensitively to differences in dosage. Even if the dosage fell minimally below the optimum concentration, it resulted in matt surfaces, while a slight overdosage produced glossy but often streaky coatings.

Despite intensive attempts to control the sensitivity of this lustre former by using chemical buffers, the results remained unsatisfactory. The buffers could not sufficiently stabilise the reactivity of the brightener, so that the deposits continued to vary greatly. The challenge was to find a method that would enable both uniform gloss formation and consistent coating quality.

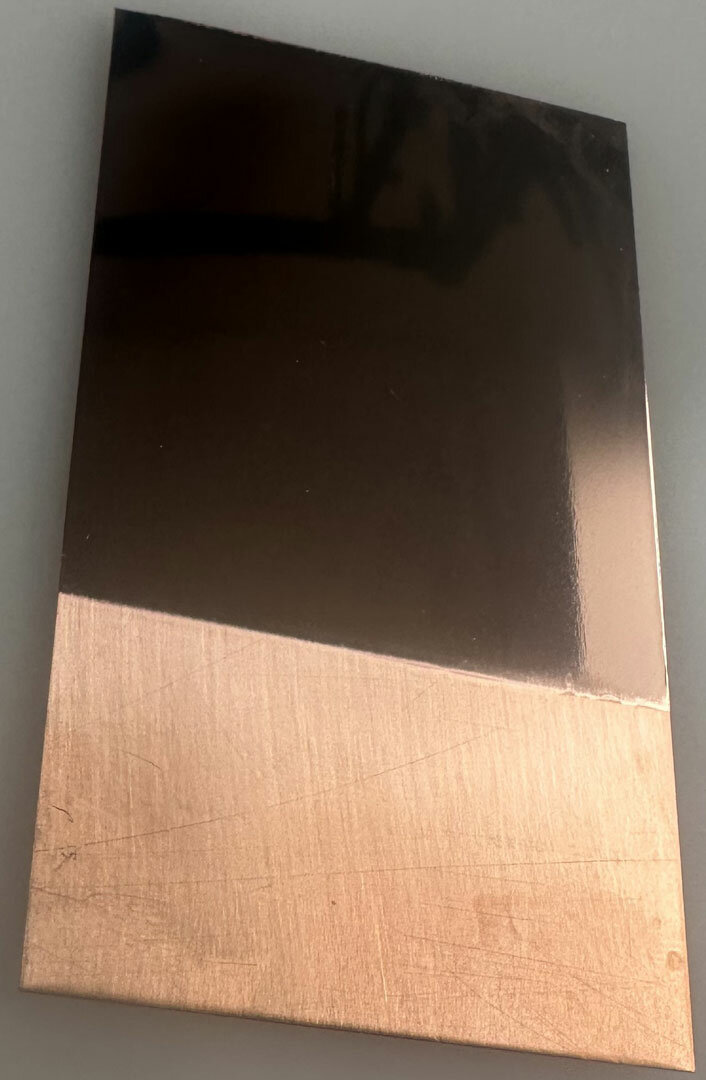

To solve these problems, we decided to change the direction of research and develop a more stable, less sensitive solution. Through intensive hybrid research, we succeeded in developing a new glossy copper plating solution that offers an excellent compromise between gloss and levelling. This electrolyte shows a uniformly shiny deposit that remains consistent even with varying dosages. It is particularly worth emphasising that the new electrolyte also delivers excellent results in pin plating, where it produces stable and aesthetically pleasing surfaces.

This new development has not only enabled us to significantly improve the quality and durability of the deposits, but also to expand the range of applications for the glossy copper plating solution. It is now a reliable solution for a wide range of applications.

Click here to go directly to the glossy copper plating solution