Scattering in the galvanising process

Here we address the very important scattering to be observed. The anode should be adapted to the shape of the workpiece to be coated. Only more current flow alone would cause it to become dark and dull in places that are closer to the anode.

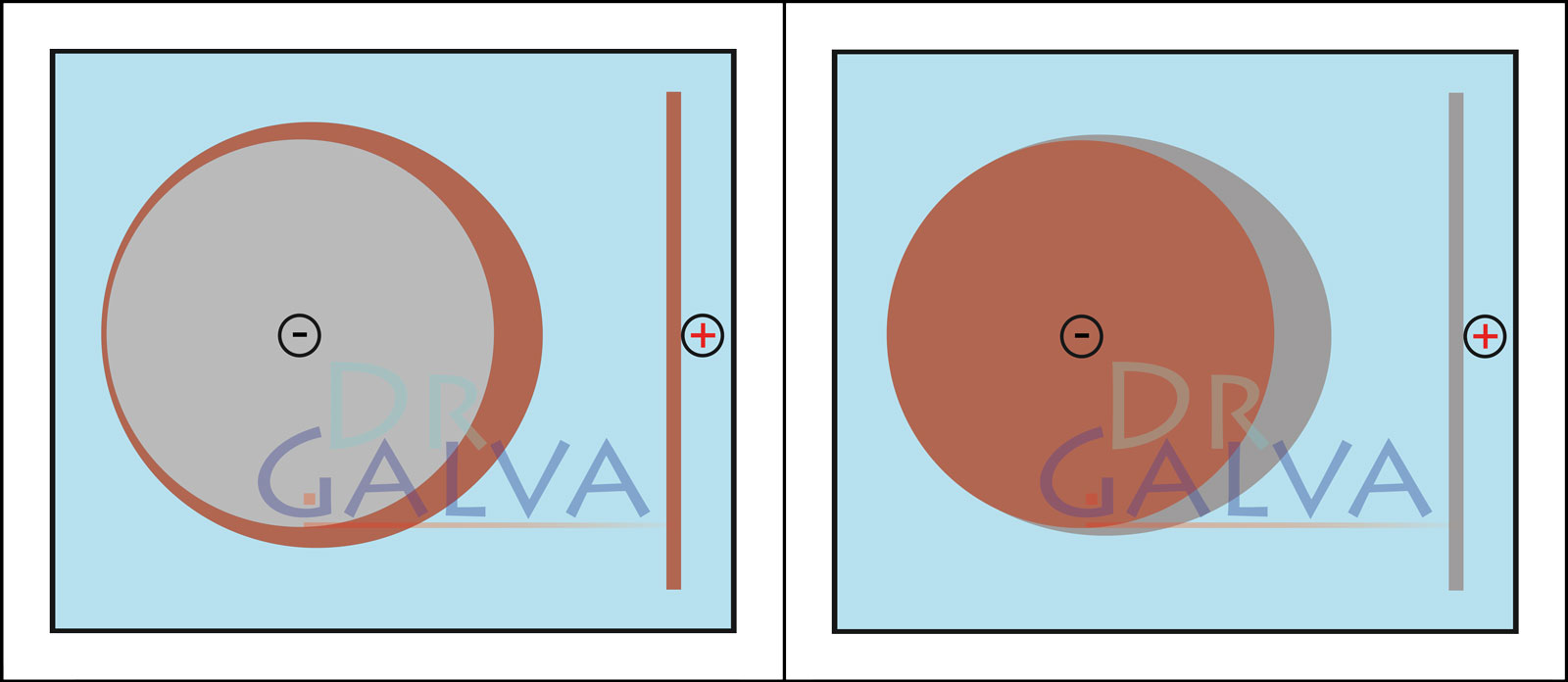

| Good scattering (e.g. copper acidic) when using a flat anode. The smaller the distance, the more current flows at these points and more metal is deposited there. Due to the good scattering, a thin layer is nevertheless deposited on the back. | Poor scattering (e.g. zinc weakly acidic). Here, metal is only deposited on the side facing the anode. Practically no current flows on the rear side and no deposition takes place there, or only minimally. |

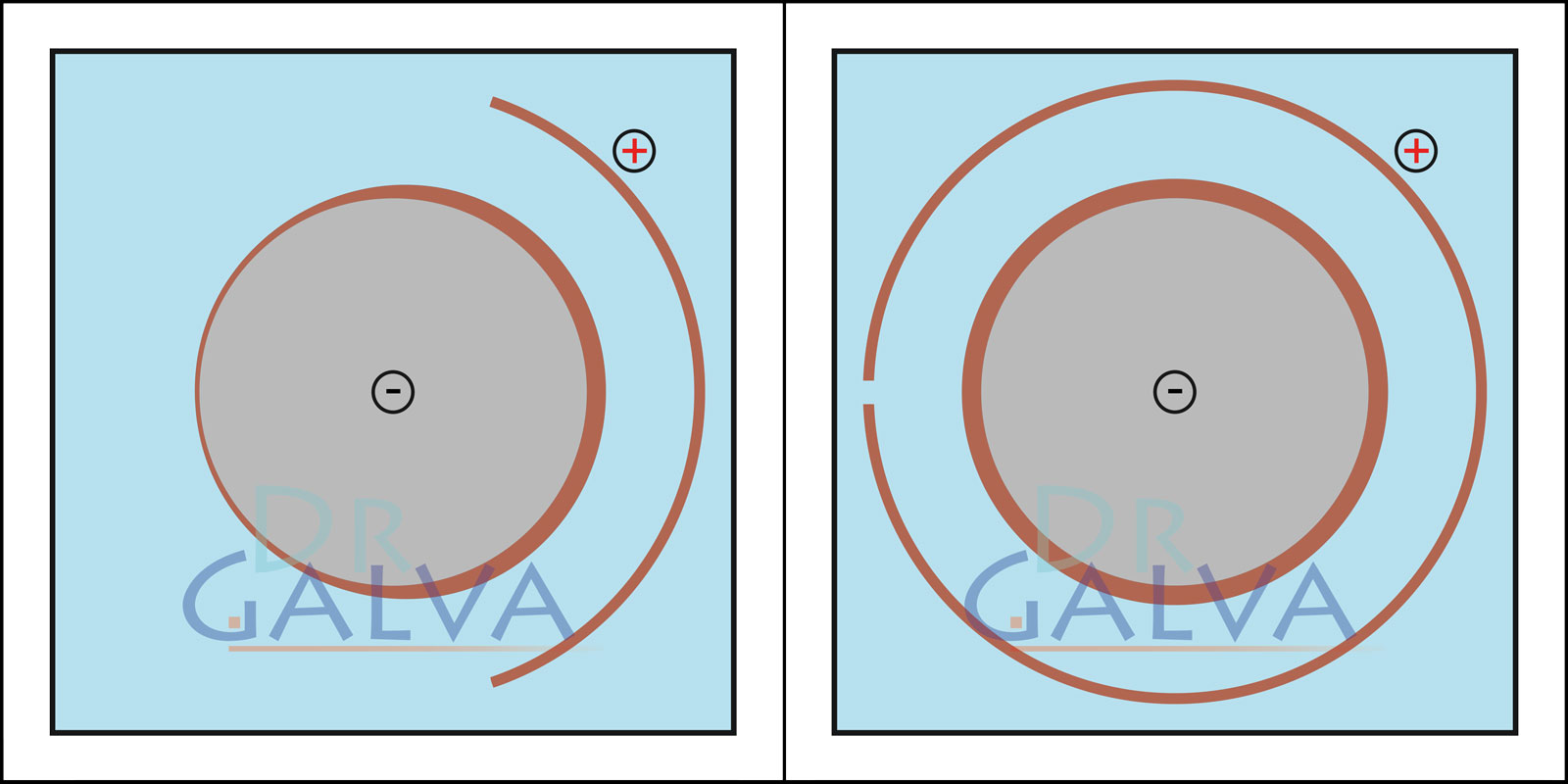

| With a shape adapted to the workpiece, the metal deposits much more evenly. On the side facing away from the anode, the layer becomes thinner. Overall, the layer becomes much more uniform compared to a flat anode. | A ring anode and the workpiece are found in the galvanic bath. This ensures that the anode distance to the workpiece is the same all around. To achieve uniform deposition, it is not necessary to rotate the workpiece |

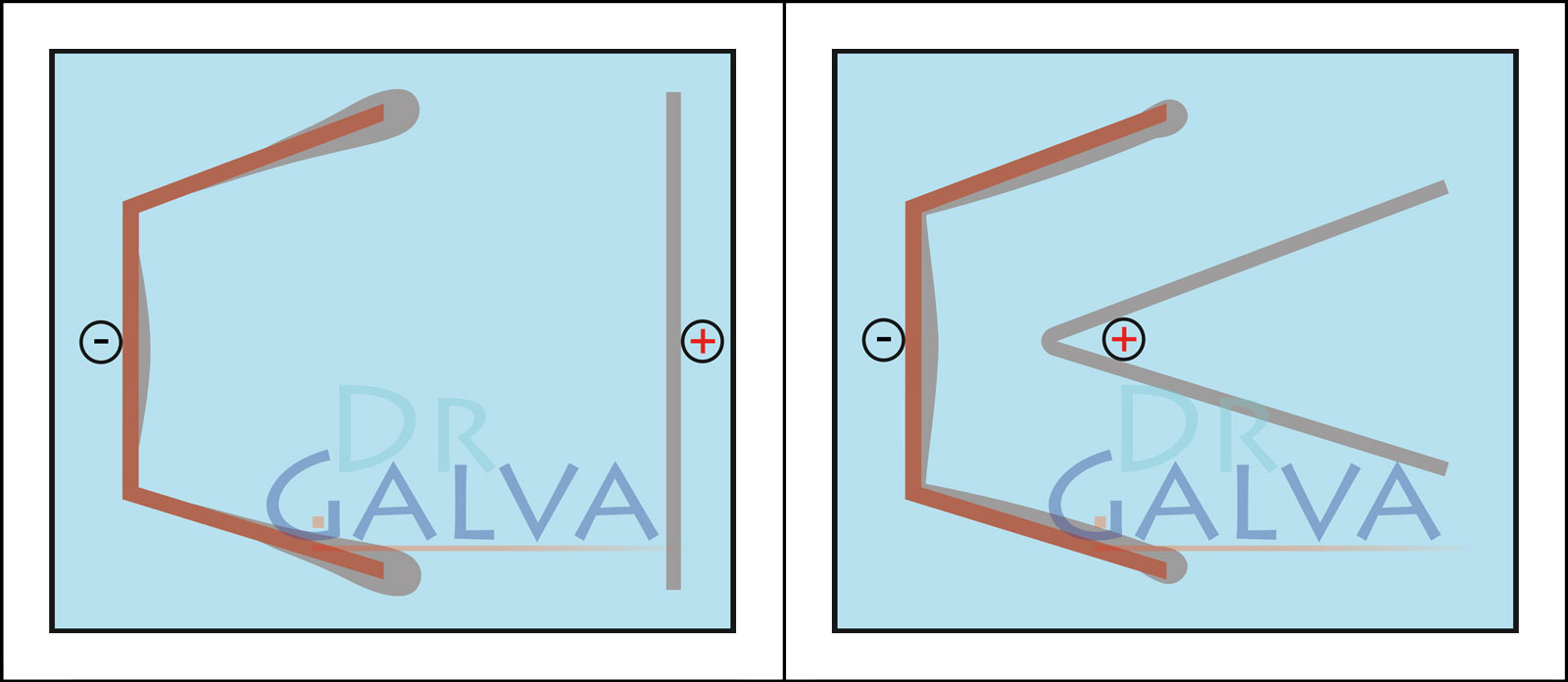

| This is the most complicated form, the metal is almost only deposited in the area facing the anode. | With an anode adapted to the mould, there is still good deposition on the inside, and the corners are also coated. However, this is quite time-consuming. |