Ultra-3 Black Oxide Solution – uniform black finish for steel

The Ultra-3 Black Oxide Solution provides reliable corrosion protection for steel workpieces. A key advantage is that it can be used at room temperature, greatly reducing effort compared with hot blackening. You need neither special equipment nor forced ventilation, and working with the room-temperature solution also lowers safety risks.

During application a black layer forms on the workpiece that, together with oils, shields it from harmful environmental influences. Ultra-3 is especially effective on low-alloy steels, including chrome-containing grades. In addition, you can dilute the concentrate up to 1 : 4 with water when treating construction steel without impairing blackening quality.

Ideal for dimension-critical workpieces

Many corrosion-protection methods add an extra coating that can cause problems on tight-tolerance parts. Black oxide does not.

The chemical reaction between the metal surface and Ultra-3 produces a layer only about two micrometres thick. This layer protects the workpiece from corrosion without affecting dimensional accuracy.

Using Ultra-3 Black Oxide Solution

Make sure the solution is at room temperature for best results. Avoid outdoor use at low temperatures.

-

Preparation: Thoroughly clean and degrease the workpiece.

-

Blackening: Dilute Ultra-3 up to 1 : 4 with water for construction steel, then immerse the workpiece. Within minutes an even black surface forms.

-

Post-treatment: Remove the workpiece, rinse well with clean water and dry. For optimum corrosion protection, treat the part with a suitable oil. The combination of black oxide and oil provides long-lasting protection.

Suitable materials

Ultra-3 is ideal for iron as well as unalloyed and low-alloy steels. For best results we recommend blackening steels with a chrome content of up to 3 %. For higher-alloy steels use our Rapid Blackening “Ultra-5” or Brush Blackening “Ultra-7”. Conventional blackening does not work on stainless steel because the necessary oxidation does not occur.

Advantages of Ultra-3

- Room-temperature application – no heating required

- Dilutable up to 1 : 4 with water on construction steel

- Flexible use anywhere with suitable ambient temperature

- No dimensional change to the workpiece

- Excellent corrosion protection in combination with suitable greases and oils

- Improves lubricant adhesion

- Optimised emergency-running properties of plain bearings

Scope of delivery:

- Ultra-3 Black Oxide Solution (single bottle)

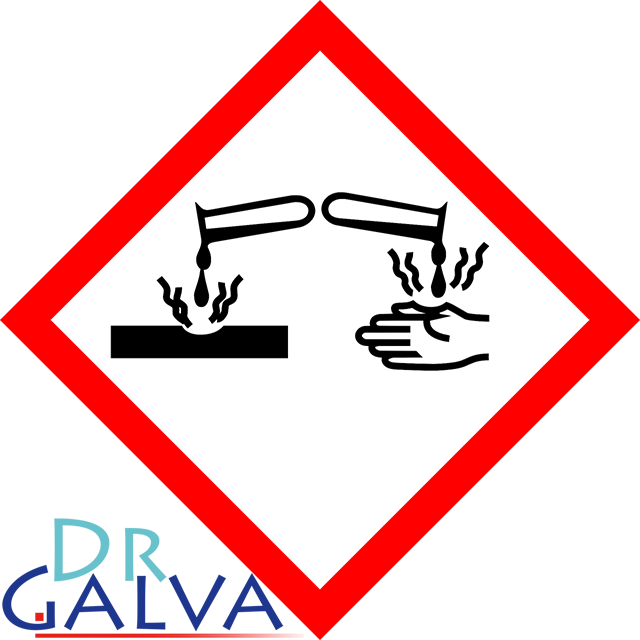

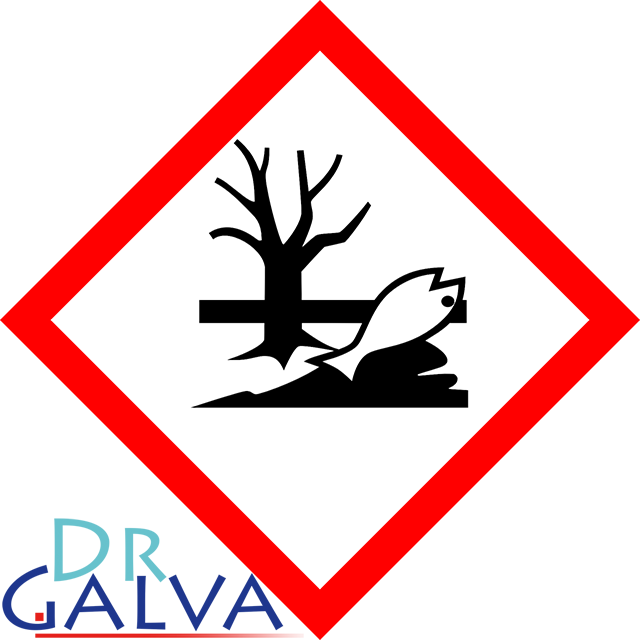

Marking of the mixture:

Ultra-3 Dip Black Oxide

(contains sodium chlorate, selenium dioxide, nitric Acid, sodium hydroxide)

Signal word: Danger

H290 May be corrosive to metals.

H302+H332 Harmful if swallowed or if inhaled.

H314 Causes severe skin burns and eye damage.

H411 Toxic to aquatic life with long lasting effects.

P101 If medical advice is needed, have product container or label at hand.

P102 Keep out of reach of children.

P260 Do not breathe mist/vapours/spray.

P280 Wear protective gloves/protective clothing and eye protection/face protection.

P301+P330+P331 IF SWALLOWED: Rinse mouth. Do NOT induce vomiting.

P303+P361+P353 IF ON SKIN (or hair): Take off immediately all contaminated clothing. Rinse skin with water or shower.

P305+P351+P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P310 Immediately call a POISON CENTER/doctor.

P501 Dispose of contents/container to an appropriate recycling or disposal facility.