Ultra-5 Quick blackening > "the easy one" - simply blacken steel quickly.

Blackening protects steel workpieces from a wide variety of environmental influences. With little effort and within a short time, you can achieve reliably effective surface protection with Ultra-5 Quick Blackening. Dip blackening is easy to apply and produces a reliably protective black blackening layer within a very short time. Since no material is applied during this process, cold burnishing is ideal for all workpieces where even the smallest changes in shape are undesirable or which react sensitively to thermal stress.

Areas of application for Ultra-5 rapid blackening

Compared to other processes, cold burnishing creates a protective layer without subjecting workpieces to thermal stress. Another argument in favour of immersion burnishing with Ultra-5 Quick Burnishing is the high dimensional accuracy that a burnished object retains. This is because, in contrast to coating, no foreign material is applied during burnishing. The process only changes the material properties of the surface through the incorporation of oxygen atoms and forms a protective layer approximately two micrometres thick.

For this reason, immersion burnishing with Ultra-5 fast burnishing is always the process of first choice when a workpiece is not to be exposed to thermal stress or when it is a matter of precision parts where even the smallest changes in shape have a negative effect on the accuracy of fit during further processing.

Ultra-5 Quick Burnishing > for which materials?

Burnishing is suitable for cast iron, hardened steels as well as for unalloyed and low-alloy steels. For these materials, the rapid blackening changes the material surface through the incorporation of oxygen. The result is a protective oxide layer (in conjunction with oiling or waxing the layer) that withstands mechanical stresses such as bending and pressure and is resistant to paints, solvents and lubricants. In principle, burnished coatings show a high resistance in alkaline environments, but dissolve on contact with acids.

Stainless steel is not suitable for classic cold burnishing. In order to blacken parts made of stainless steel, special processes such as black oxidation or blackening at high temperatures are required.

How to achieve optimal results with burnishing

How well the burnishing works depends on the pre-treatment of the workpiece. Remove all impurities and any coatings with special care and avoid contamination with silicone greases or silicone oils at all costs. If an object is contaminated with these greases or oils, please be sure to remove them with appropriate special cleaners before cold burnishing. This is because high-quality burnishing is only possible with an absolutely clean surface.

Fill the bluing agent into a suitable container and immerse the workpiece in the solution for a few seconds. Finally, dry the burnished object and oil the surface well. In this way, you get a durable and reliable protection against a wide range of environmental influences.

Burnishing with Ultra-5 Quick Burnishing has several advantages

In addition to the aforementioned resistance of a workpiece to a wide variety of environmental influences, rapid burnishing with the burnishing agent also offers other advantages. For example, lubricants adhere better to the surface and lubricated plain bearings have improved emergency running properties. In the case of sliding surfaces, it has been proven that the risk of cold welding is significantly reduced.

Identification of the mixture:

Ultra-5 quick burnishing solution

(contains selenium dioxide, copper sulphate, potassium hydrogen difluoride, nickel sulfate)

Signal word: Danger

H290 May be corrosive to metals.

H314 Causes severe skin burns and eye damage.

H317 May cause an allergic skin reaction.

H332 Harmful if inhaled.

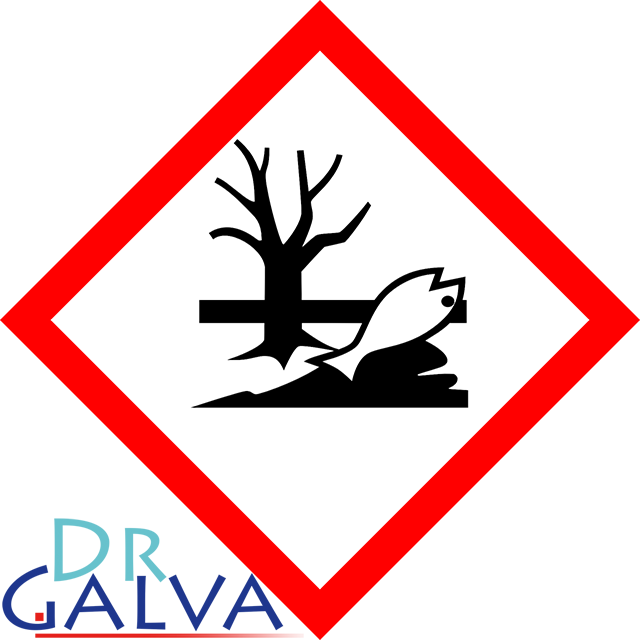

H411 Toxic to aquatic life with long lasting effects.

P102 Keep out of reach of children.

P103 Read carefully and follow all instructions.

P260 Do not breathe dust/vapours/spray.

P280 Wear protective gloves/protective clothing/eye protection/face protection.

P301+P330+P331 IF SWALLOWED: Rinse mouth. Do NOT induce vomiting.

P302+P352 IF ON SKIN: Wash with plenty of water.

P333+P313 If skin irritation or rash occurs: Get medical advice/attention.

P305+P351+P338 IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing.

P310 Immediately call a POISON CENTER/doctor.

P501 Dispose of contents/container according to regional/national regulations. Do not discard with household waste.